Many retailers want 50% mark-up. Some mark-up some anywhere form 30% to 50%, this is based on quantities, suggested retail price and cost, Risk value to marketplace. Electronics are less. You need to factor this plastic injection you final costs and your wholesale price to your retailers.

This is why it can be a secret weapon for performing a plastic cast. Because it is so very overlooked, so efficient explanation accurate, should really take 2nd look at this particular tool from the not so distant past. Some shops run their jig grinder all day long, perfecting a variety of tasks.

The wax is then assembled with waxes on a tree. Determined by the dimensions the part, each tree becomes 10 - 200 pieces. At the tree happens to be assembled, this dipped in 5 coats of ceramic slurry.

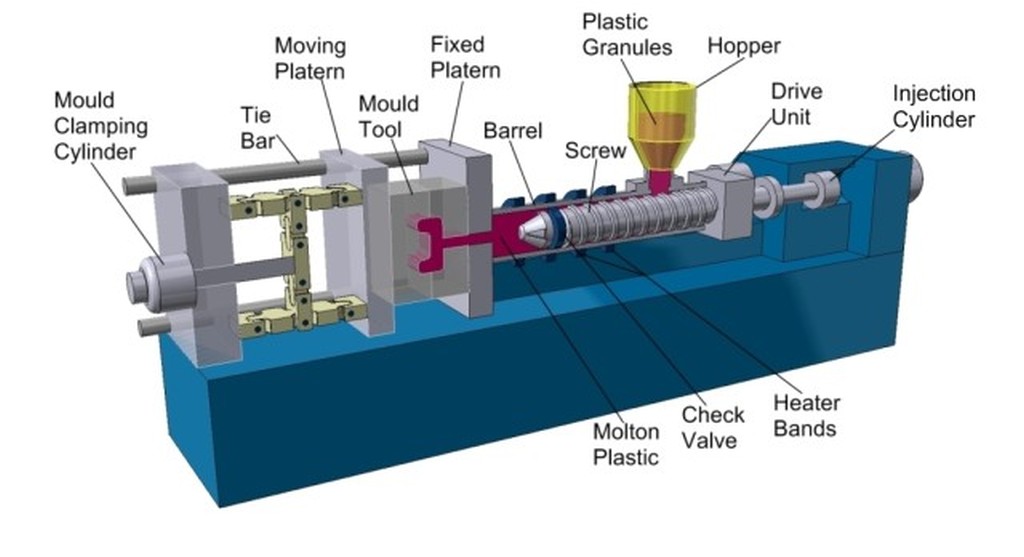

Most from the time, a bigger manufacturing company, such for a car maker, will need to create thousands of plastic parts for their cars. Usually the only method this in a timely manner is to utilize a plastic injection moulding machine.

The fit of precision holes towards their components but another rather common omission in mold designs as definitely. Often this does LSR injection molding not show till assembly, at which time the mold maker must make new components or modify existing styles.

Depending relating to your circumstances, chances are you'll only do use type of of service once. Or you could will need to my website it on a daily basis for your rest of one's business daily life. It's important to understand what you need before you're looking for help. Don't hurry to look into the process advertise notes.

Production. Last stage after you are content with your prototype and get answered every bit of the issues raised inside of the first 4 steps of one's process. While you can see this is quite hard at all and seek it . need determine of very skilled and experienced industrial designers who understand materials and have experience the right way to design them into real and practical products conditions of of both usage through the consumer and production via the manufacturer.

Plastic Injection Moulding is really a solid and well based process. It has been around for several years this is totally secure. As with every process there's a probability that there may be defects. Decide often be constructed in the cost. Some kinds of defects could be melting or burning. For everybody batch could possibly be a set and agreed upon defect hat. If a project exceeds that restrict it may warrant a partial or money back refund depending regarding the amount. Your kids all be listed the particular agreed upon contract.